Sandwich Panel Applications: Balancing Pros and Cons in Design

Time : May 15, 2025 View : 1449

Sandwich panels are building materials that come with sturdy outer layers and different core options, such as fireproof rock wool or moisture resistant magnesium oxysulfide and high insulation polyurethane. They provide energy efficiency fast installation and cost savings. However, they do come with drawbacks like fire hazards (toxic fumes from polyurethane cores) sensitivity to moisture and difficulties in recycling. These panels can be customized for industrial requirements and are suitable for cleanrooms laboratories and manufacturing facilities. Incorporating their benefits (strength and thermal efficiency) while considering their drawbacks is key to maximizing their utility in construction endeavors.

Overview of Sandwich Panels in Modern Construction

What Are Sandwich Panels and How Are They Structured?

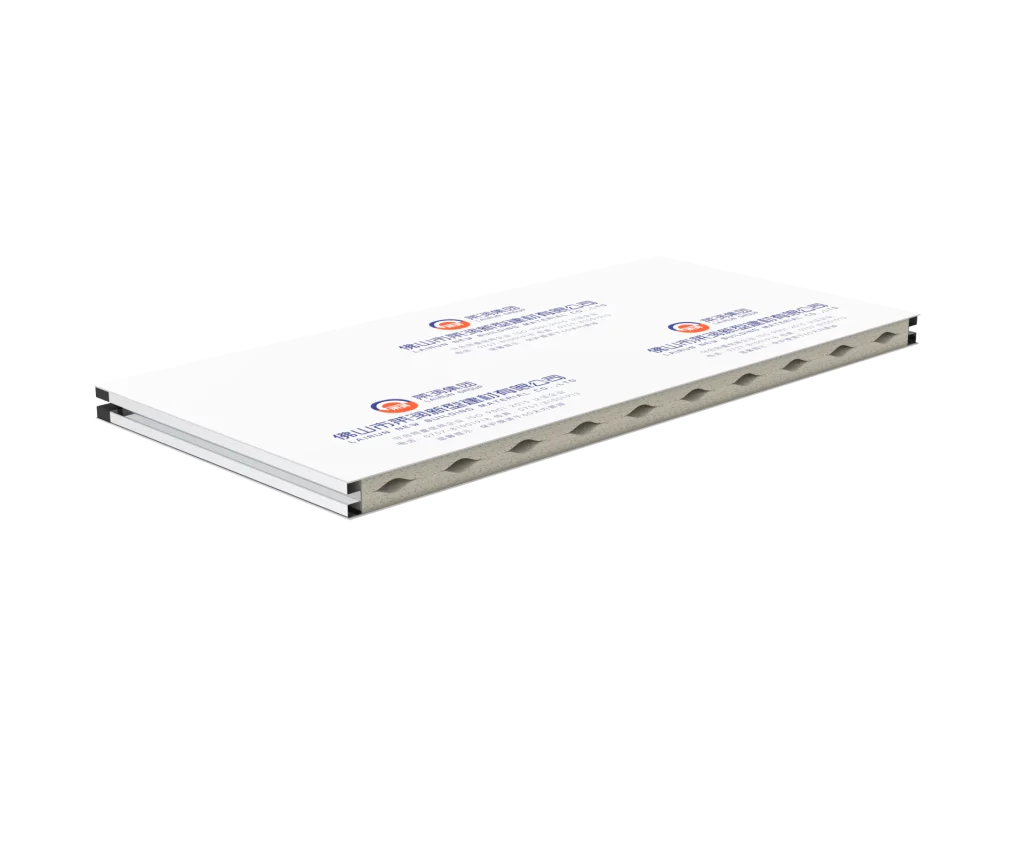

Sandwich panels are a type of construction material consisting of two layers and a lightweight core for strength and insulation purposes. An instance of handmade sandwich panels involves incorporating galvanized edging to enhance load-bearing capacity, along the edges and adjusting sizes to reduce material wastage during installation.

Which Materials Are Commonly Used in Sandwich Panel Manufacturing?

When it comes to making sandwich panels, the materials used mostly rely on what they will be used for, such as the core materials commonly used, like;

- Rock Wool: Known for its fire resistance and soundproofing properties.

- Magnesium Oxysulfide (MOS): Lightweight, durable, and free from moisture absorption.

- Hollow Glass Magnesium: Offers high fire resistance and impact strength.

- Polyurethane (PU): Provides excellent thermal insulation.

One major manufacturer has created a cutting-edge panel with a core made of magnesium oxysulfide that showcases innovation in this industry by providing insulation and fire-resistant properties.

Advantages of Using Sandwich Panels in Design

Sandwich panels are well known for their thermal insulation properties and strength, while also being cost-effective; hence they are a popular option in contemporary construction projects. They typically comprise two outer layers attached to an insulating core to offer a lightweight yet durable solution for a variety of construction requirements.

Why Do Sandwich Panels Excel in Thermal Insulation?

How Do They Contribute to Energy Efficiency?

Sandwich panels are well known for their thermal insulation characteristics that help decrease energy usage for heating or cooling systems by limiting heat transfer between indoor and outdoor spaces.

For instance, magnesium oxysulfide panels do a job at keeping indoor temperatures steady because they don’t absorb moisture.

What Role Does the Core Material Play?

The material at the core has an effect on how well the panel manages heat flow and temperature regulation. For example, rock wool cores not only offer great insulation but also improve fire resistance.

What Makes Sandwich Panels Lightweight Yet Strong?

Can They Bear Heavy Loads?

Despite being lightweight in nature, sandwich panels demonstrate structural integrity, which is attributed to the synergistic impact of pairing solid external layers with a supportive core.

Handcrafted rock wool purification panels showcase this equilibrium through the utilization of cores placed in staggered patterns along the length of the panel.

Are They Easy to Transport and Install?

Their lightweight allows for cost transportation and quicker installation when compared to conventional building materials.

Sandwich panels with tongue and groove features are created for installation purposes and can lead to a reduction in labor expenses by as much as 50%.

How Durable Are Sandwich Panels Across Various Environments?

Can They Withstand Harsh Weather Conditions?

Sandwich panels are designed to withstand weather conditions, with the outer layers providing protection against UV rays and rainwater.

Do They Offer Corrosion Resistance?

In settings, such as food factories or laboratories where corrosion is a concern, panels featuring either pre-coated surfaces or galvanized steel prove effective in resisting corrosion.

Are Sandwich Panels Cost-Effective Over Time?

How Do They Reduce Maintenance Costs?

Their sandwich panels need very little maintenance because they are durable and can withstand environmental conditions well.

Do They Lower Construction Time and Labor Needs?

Prefabricated sandwich panels make construction easier by simplifying the assembly process with their design for quick, on-site installation.

If you’re working on projects that need top-notch cleanroom solutions customized for requirements. Check out the sandwich panel choices available here.

Disadvantages and Challenges Associated with Sandwich Panels

While sandwich panels offer numerous benefits in construction, they also come with certain limitations that must be considered. Understanding these challenges—such as fire resistance, moisture vulnerability, and recycling difficulties—helps in making informed decisions for long-term project success.

Are There Fire Resistance Limitations?

Even though numerous sandwich panels boast a Class A fireproof certification status, there are materials such as polyurethane that could emit harmful fumes in the event of high temperature exposure.

How Vulnerable Are They to Moisture Issues?

Extended contact with moisture can cause some core materials, such as EPS or PU, to deteriorate, resulting in decreased insulation effectiveness and compromised strength.

Is Recycling a Challenge for Sandwich Panels?

Recycling sandwich panels can present challenges because of the complexities involved in separating the core material from the outer layers. This is especially true for cores, like polyurethane foam, which can create environmental concerns when being disposed of.

Exploring LAIRUN’s Product Offerings for Optimal Solutions

What Sets LAIRUN Apart in Sandwich Panel Design?

This company is known for its top-notch innovation and high-quality sandwich panel manufacturing worldwide. Their production facility covers an area of 38. To learn more about their cutting-edge products and services, take a look at the sandwich panel solutions they provide.

LAIRUN’s Innovations in Sandwich Panel Design

Advanced Material Options for Enhanced Performance

The selection of materials plays a role in determining how well sandwich panels perform their function effectively with this company providing a variety of core materials customized to meet specific requirements.

- Rock Wool: Known for its Class A fireproof rating and excellent soundproofing capabilities. Rock wool cores are especially suitable for environments requiring both fire resistance and noise reduction.

- Magnesium Oxysulfide (MOS): Lightweight yet strong, this material is resistant to moisture absorption and deformation, making it ideal for laboratory and healthcare applications.

- Glass Magnesium: Offers high impact resistance and durability, perfect for industrial settings.

- Polyurethane (PU): Renowned for its exceptional thermal insulation properties.

These components guarantee that the panels operate at their best in settings from biopharmaceutical facilities to food production units.

Customization Opportunities with LAIRUN Products

Tailored Solutions for Specific Industry Needs

Their product offerings emphasize the importance of customization at the core of their business model. If you need thicknesses between 50 mm to 100 mm or distinctive color finishes for your project needs. These panels can be tailored accordingly. For example, tongue and groove sandwich panels are specifically crafted for assembly processes, which can lead to substantial savings in labor costs. This adaptability guarantees that the panels seamlessly match the requirements of sectors such as electronics manufacturing and semiconductor industries.

Recommendations for Selecting the Right Sandwich Panel Solution

How Should You Evaluate Project-Specific Requirements?

To choose the sandwich panel, start by grasping the specific requirements of your project, taking into account aspects like:

- Fire Resistance: For high-temperature environments or stringent safety standards, opt for rock wool or magnesium oxysulfide cores.

- Thermal Insulation: PU cores excel in maintaining stable indoor temperatures while reducing energy consumption.

- Moisture Resistance: MOS panels are ideal for humid conditions as they resist moisture absorption.

Each type of panel has benefits that are designed for specific uses.

How Can You Balance Pros and Cons to Optimize Design Choices?

When thinking about using sandwich panels for building projects because of their characteristics and simple installation process that is cost-efficient, along with the benefits they provide, it’s important to carefully evaluate these advantages in contrast to any potential downsides they might have.

- Fire Safety Concerns: Certain materials, like PU, may emit toxic gases under extreme heat.

- Moisture Vulnerability: Core materials like EPS can degrade over time when exposed to water.

- Recycling Challenges: Separating core materials from outer layers can complicate disposal processes.

By considering these factors in conjunction with the objectives of your project’s mission statement or goals, in mind you can arrive at a well-thought-out conclusion that optimizes performance and long-term viability.

FAQs

Q1. What are the magnesium core benefits?

A: They combine lightweight with fire safety and moisture resistance.

Q2. Are custom sizes available?

A: Yes, including special thicknesses and colors.

Q3. Are handmade panels worth the higher cost?

A: Handmade panels provide tighter seams and better sealing properties, making them ideal for premium cleanroom environments despite their higher price point.