How to Determine the Optimal Thickness for Cold Room Panels

Time : May 08, 2025 View : 1457

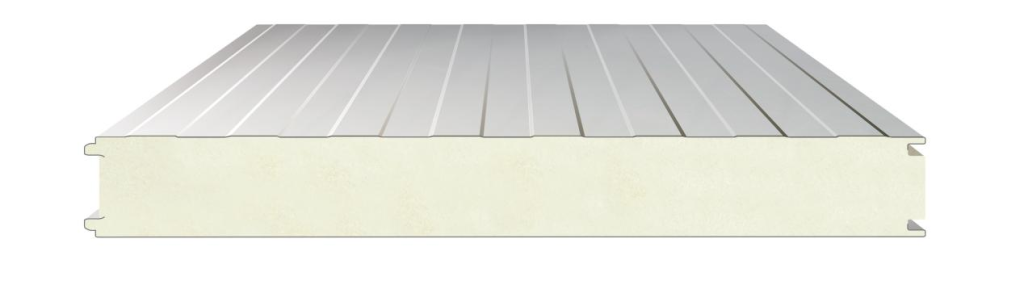

Choosing the panels for a cold room is based on factors such as insulation requirements, temperature regulation needs, surrounding conditions and meeting industry regulations. Thicker panels of 100 mm or more are ideal for ensuring thermal efficiency in freezers while chillers can work well with 50 to 75 mm panels. Insulating materials like polyurethane (PU) are known for their energy saving properties, polystyrene (PS) is a budget option and advanced choices, like magnesium oxysulfide provide improved fire resistance and durability. Tailored solutions like the ones offered by Lairun Group provide options for customized thickness ranging from 50 to 150 mm and various material choices such as rock wool for improved fire resistance capabilities. Choosing the panels involves striking a balance, between initial expenses and long term energy efficiency benefits while ensuring structural integrity and meeting industry standards.

Factors Influencing the Selection of Cold Room Panel Thickness

Why Are Thermal Insulation Needs Crucial?

Cold room panels are primarily utilized for temperature regulation in settings. Their ability to insulate effectively is essential for maintaining desired temperature levels efficiently. Thicker panels provide insulation by reducing heat transfer and energy loss. In settings such as freezers that require zero temperatures for optimal operation the thickness of the panels becomes a critical factor for optimal performance.

Different materials have varying effects on the retention or loss of heat in a space based on their insulation properties with Polyurethane (PU) and polystyrene (PS) being recognized for their effectiveness as insulators that can lead to energy and cost savings when carefully selected in terms of thickness and material choice.

How Does Temperature Control Determine Panel Thickness?

In a room setting like this one here the thickness of the panels is quite important and depends a lot of what temperature control requirements are in place at the time. If you’re dealing with low temperatures around 18 ℃ or below that mark, thicker panels are needed to do a good job at keeping outside heat from seeping in efficiently, whereas in less extreme situations thinner panels would work just as well for the job.

Additionally the thickness of the panels influences the durability of the room. Thicker panels provide robustness and longevity, which are essential in industrial settings with heavy machinery or frequent movement.

What Role Do External Environmental Conditions Play?

Variations in the surroundings, such as humidity levels and sun exposure can impact the performance of cold room panels significantly. In regions, with humidity or frequent temperature fluctuations utilizing panels can hinder moisture infiltration and maintain stable indoor conditions effectively.

In places where it rains frequently, it’s advisable to use panels with enhanced resistance to moisture to prevent degradation over time. Applying UV coatings on the layer can protect against harm from prolonged exposure to sunlight.

Are Regulatory Standards Important?

Making sure that the cold room panels meet the safety and performance standards is vital in meeting the requirements set by different industries that have strict regulations, on thermal insulation effectiveness and fire safety to ensure operational reliability and safety.

Regulatory bodies often set thickness standards based on the intended purpose of the material – be it for storing food items or pharmaceutical goods or for industrial use in general. Making sure to follow these guidelines not only protects your investment, but also ensures you’re meeting your legal obligations effectively.

Material Composition of Cold Room Panels

What Are the Common Materials Used?

Some cold storage setups may need materials aside from PU and PS to cater to their unique requirements. Polyisocyanurate (PIR), for example, is preferred for its fire resistance and excellent thermal properties making it a great fit for high security settings. Its sturdy closed cell composition offers resilience and protection against moisture maintaining effectiveness over periods in challenging situations.

Polyurethane (PU) Panels: Why Are They Preferred?

Polyurethane is widely recognized for its heat insulation capabilities due to its low thermal conductivity characteristics. It is lightweight yet durable making it ideal for refrigerated spaces aiming to conserve energy. PU panels are commonly employed in environments where maintaining low temperatures is crucial.

Polystyrene (PS) Panels: Where Do They Excel?

Polystyrene offers cost insulation compared to polyurethane making it a good choice for scenarios with budget constraints but a need for decent insulation, although it may be less efficient in extremely cold conditions.

What About Other Insulation Materials?

Certain materials like rock wool and magnesium oxysulfide are favored for their fire noise reducing properties in environments such as cleanrooms or industrial settings where safety is a top priority.

Why Choose Advanced Cold Room Panel Materials?

The sandwich panel featuring a core composed of magnesium oxysulfide stands out as a choice available in todays market that provides excellent thermal insulation and fire resistant properties while addressing common industry challenges such as durability and sound performance issues effectively. Crafted by professionals with over two decades of knowledge in the field of cleanroom panel research and development this material showcases a blend of expertise and innovation. Insights into tailored solutions that cater to your unique needs we recommend exploring the diverse selection of top notch cleanroom panels available.

Evaluating Panel Thickness for Different Applications

Which Thickness Is Optimal for Freezers?

Freezers operating at 18 ℃ or lower typically need panels that’re at least 100 mm thick to enhance performance minimize heat transfer and boost energy efficiency for extended periods of operation. Thicker panels also play a role in reinforcing the freezers structure in conditions.

What About Chillers?

Chillers designed to maintain temperatures between 0°C and 8°C can utilize panels ranging from 50 mm to 75 mm thick to achieve a combination of cost effectiveness and efficient insulation capabilities.

Are There Special Considerations for Industrial Cold Storage?

Cold storage facilities in this industry frequently require solutions due to their extensive scale and complex operational layout. The thickness of panels may vary depending upon the areas within the facility. For example thicker panels are employed in freezer zones whereas thinner ones are used in loading areas. Additionally to enhance safety protocols fire resistant materials, like magnesium oxysulfide could be integrated into sections of the facility.

Energy Efficiency and Cost Implications of Panel Thickness

The Relationship Between Insulation Thickness and Energy Savings

When evaluating how well cold room panels insulate against heat loss or gain is key to consider the thickness of the panels as it plays a role in their effectiveness at blocking heat transfer. This can directly affect energy consumption levels. When dealing with scenarios that require temperatures below freezing, such as storage for goods or pharmaceutical freezers it is usually necessary to use panels that are thicker than 100 mm to achieve optimal thermal performance. This helps reduce the workload of cooling systems and leads to energy costs, in the long run. Polyurethane (PU) is recognized for its thermal conductivity and lightweight characteristics that make it highly effective in a wide range of applications.

Boosted insulation thickness provides benefits beyond energy conservation— it also contributes to bolster the panels structure to aid the cold room in enduring external elements such as temperature shifts and humidity variations successfully— a crucial factor in industrial settings prioritizing reliability and consistent performance.

Balancing Installation Costs with Long-Term Operational Benefits

Thicker panels offer insulation and resilience but come with higher initial costs, for both materials and installation.

Choosing the thickness of the panel depends on the needs of your application setting. For sites operating in varying temperatures consider using panels ranging from 50 mm to 7 mm. These options provide a balance between cost effectiveness and adequate insulation. Alternatively in environments, with temperatures or high humidity levels it is essential to select thicker panels to guarantee effectiveness and compliance with industry standards.

Custom Solutions Offered by Lairun Group for Cold Room Panels

Tailored Panel Thickness Options for Diverse Needs

When it comes to selecting the thickness for your panels it’s not a one size fits all decision; it requires careful consideration of your facilitys specific needs. This is where customized solutions truly shine. Lairun Group excels in providing tailor made cold room panels that are personalized to meet industry demands. Options range from panel thicknesses of 50 mm to 150 mm with a choice of materials like rock wool and magnesium oxysulfide— ideal for use in sectors such, as biopharmaceuticals, food production and electronics manufacturing.

Their core panels made of magnesium oxysulfide offer both insulation and fireproof properties that are ideal for use in laboratories or facilities requiring stringent safety protocols to be in place. They also possess resistance against moisture which ensures longevity in environments with humidity levels. Additionally the rock wool panels they offer provide soundproof capabilities along, with a Class A fire resistance rating.

How Lairun Group Ensures Superior Quality and Performance Standards

The success of cold room panels significantly influences their performance and durability over time. The Lairun Group leverages automated production facilities to ensure precision and consistency in their merchandise. Their rigorous quality assurance protocols include shipping inspections to ensure that every panel adheres to the industrys stringent quality benchmarks.

Furthermore the Lairun Group has developed formulas for key materials such as magnesium oxysulfide to tackle concerns such as humidity absorption and structural decay with great success. This progress highlights their commitment to enhancing cleanroom technology. Select a provider with over two decades of expertise in exploring and enhancing cleanroom panels to guarantee the reliability and efficiency of your refrigeration room facilities.

FAQs:

Q1. What factors determine optimal panel thickness for facility construction?

A: When you’re choosing the thickness of panels for your construction project at the facilities sites you need to consider factors, such as the temperature requirements of the facility environmental factors. It is important to consider when deciding on panel thickness. The use of panels can provide better insulation properties, even if it may require a larger initial investment cost upfront cost in the beginning. But this can lead to better insulation properties in the long run.

Q2: Can cold room panels be customized for specific project needs?

A: Of course you have the flexibility to adjust the size of cold room panels according to your specific requirements as different companies offer customization choices varying from 50 mm to 150 mm thickness to match the needs of your project.

Q3. What materials are recommended for situations where fire resistance against fires is needed?

A: Magnesium oxysulfide or rock wool that are recognized for their thermal insulation capabilities.